Powder coating for containers is a new type of coating used for container surface coatings. It boasts environmental friendliness, high efficiency, and excellent performance, and is gradually becoming a mainstream choice for container coatings.

? Superior environmental performance: No solvent dilution is required, and the production process produces zero VOC emissions. Furthermore, waste powder can be recycled and reused, achieving a truly "zero-pollution" approach.

? Significant cost-effectiveness: Reduced diluent usage allows performance requirements to be achieved with a single coat, significantly reducing energy consumption and labor costs.

? Improved coating efficiency: Electrostatic spraying achieves a single coat, eliminating the need for multiple drying cycles. Coating time per container is reduced to 1.5-2 hours, resulting in a uniform and controllable coating thickness and a rework rate of less than 1%.

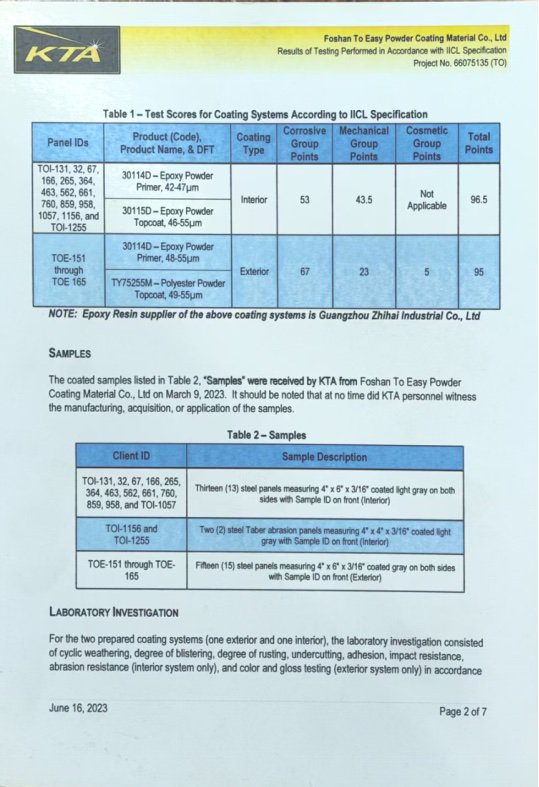

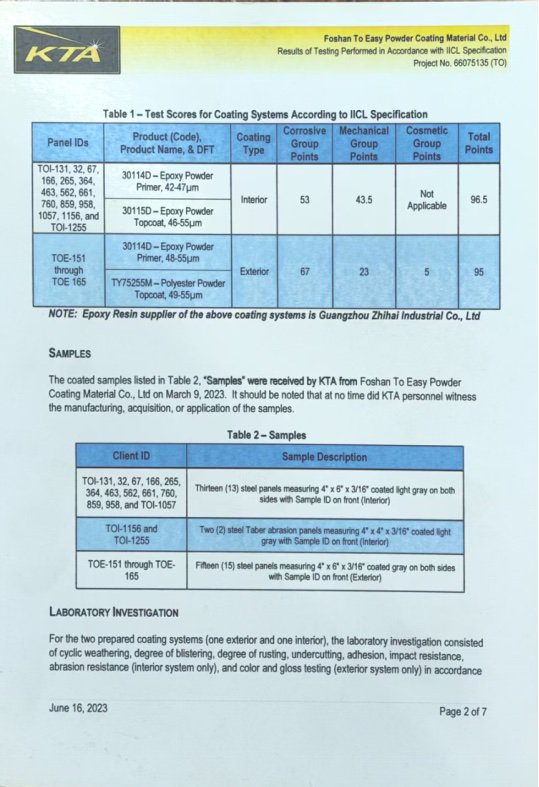

? Excellent performance: Powder coating offers superior corrosion resistance and adhesion compared to traditional coatings. It offers up to 2,000 hours of salt spray resistance and 30% improved weather resistance. Even in the intense sunlight near the equator, it is guaranteed to remain rust-free for five years. Its integrated internal and external corrosion protection improves protection by 50% for traditionally vulnerable areas such as welds and corners. ?Interior coating system: Typically, an epoxy primer + epoxy topcoat are used. They require high corrosion resistance and mechanical properties to withstand the sealed, humid environment inside the box.

?Exterior coating system: Typically, an epoxy primer + polyester topcoat are used. They prioritize corrosion resistance to withstand the erosion of complex outdoor environments such as sunlight, rain, and seawater.