Driven by users' pursuit of metallic textures and effects, market demand for metallic powder coatings is growing. Currently, the market primarily relies on metallic-effect paints, which are costly, have weak coating hardness, and low utilization rates. Furthermore, paint's VOC emissions seriously pollute the Earth's ecological environment and impact human health. With the continued advancement of China's green development policies and the implementation of local environmental regulations, the shift from paint to powder coatings is becoming a widespread trend.

Tuyi, leveraging over a decade of technological expertise and continuous collaboration with leading equipment and material suppliers both domestically and internationally, offers bonding technology for metallic powder coatings, offering users an excellent alternative to paint. These environmentally friendly products contribute to sustainable development for both humans and the environment.

Definition and Classification of Metallic Powders

Metallic-effect powder coatings, in simple terms, are various powder coatings that combine ordinary powder with metallic pigments (such as silver aluminum powder, mica powder, and bronze gold powder) through a mixing process. They create a bright, luxurious decorative effect.

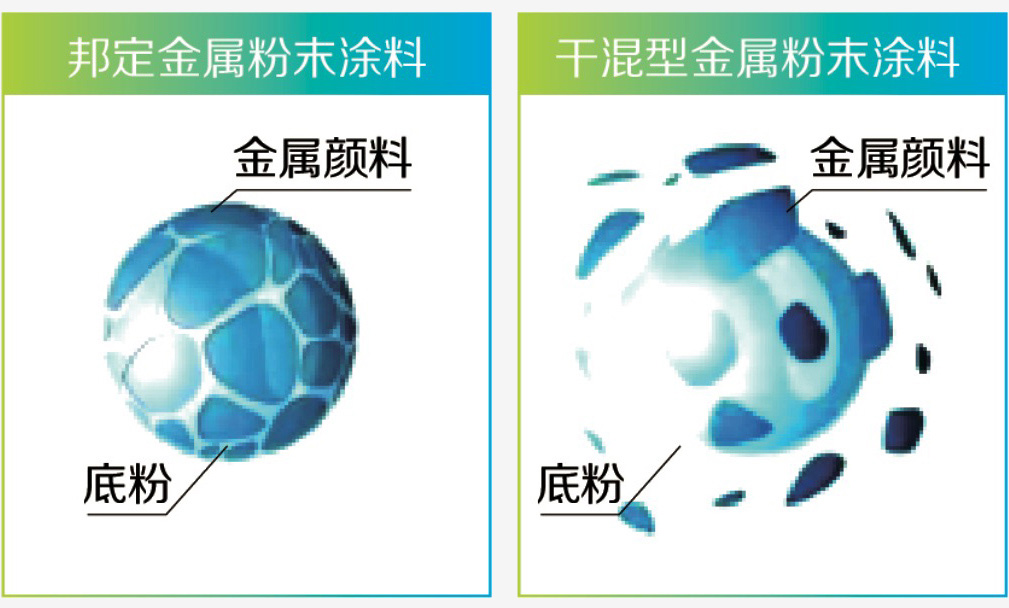

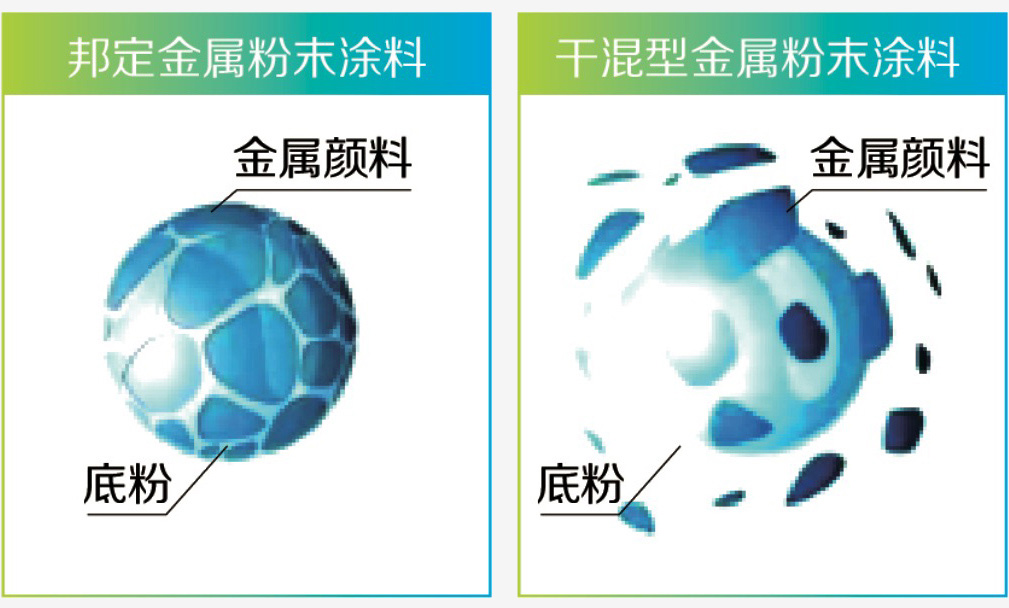

Metallic Powder Bonding Principles

The bonding technology between powder coatings and metallic pigments first appeared in 1980. At that time, an Austrian metallic shimmer pigment company called Benda-Lutz introduced the bonding process in continental Europe. Later, European powder coating companies were the first to successfully apply thermal bonding technology to powder coating production. Powder coating bonding technology, also known as thermal bonding, primarily uses frictional heating or jacket heating to create a certain degree of adhesion on the surface of powder particles, allowing the metallic effect pigment to bond with the powder base. Specifically, the high-speed rotation of the bonding machine's agitator creates high-speed collision and friction between the powder and the metallic effect pigment, the powder, and the bonding machine (agitator, cylinder wall). Over time, the surface temperature of the powder particles rises to a certain level, softening the powder surface and bonding the metallic effect pigment particles to the powder coating particles.

Tuyi Second-Generation Bonding Metallic Effect Powder Series

Tuyi offers customers second-generation bonding metallic powders with rich colors and excellent performance. Its unique formula, advanced equipment, and rigorous process deliver outstanding quality. The metallic pigment and base powder bond well, preventing separation and achieving a uniform metallic color. This solves the industry pain point of metallic pigment accumulation, provides consistent color from batch to batch, and offers a high recyclability rate, significantly reducing the overall cost of metallic powder coatings.

Product Applications:

Architectural aluminum, aluminum walls and metal furniture, baby strollers, home appliances, high-end hardware accessories, mountain bikes, digital products, car wheels, and automobiles.